Bending machines play a pivotal role in transforming raw metal into functional and aesthetically pleasing components. At Cojafex.com, we recognize the diverse needs of our clients and strive to provide cutting-edge bending solutions that enhance both the quality and performance of their products.

This blog explores the significance of bending machines, their various applications, and why partnering with Cojafex.com can elevate your manufacturing processes.

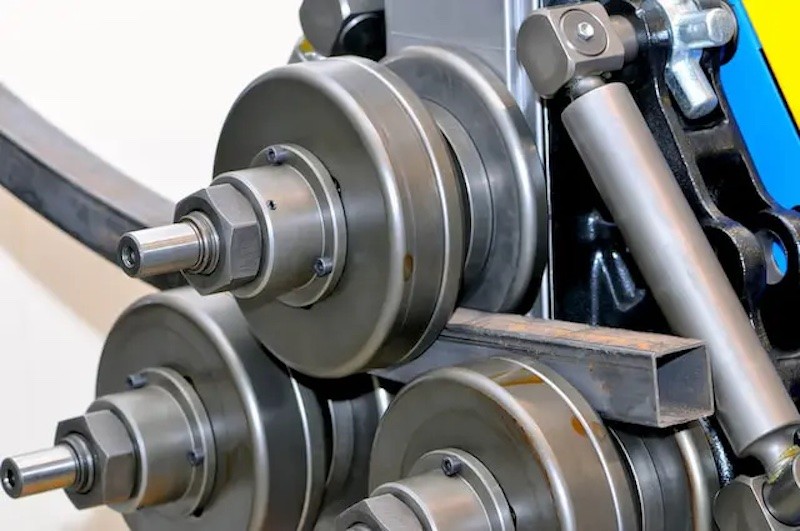

The essence of bending machines

Bending machines are indispensable tools in the metalworking industry, designed to alter the shape of metal sheets, bars, and tubes through controlled force. These machines ensure that materials are bent to precise angles and dimensions, maintaining structural integrity and meeting specific design requirements. Whether it’s creating simple bends or complex geometries, bending machines offer the versatility needed to accommodate a wide range of projects.

The fundamental operation of a bending machine involves clamping the material between a punch and a die. As the punch descends, it applies force to the material, causing it to bend around the die. The sophistication of modern bending machines allows for adjustments in force, speed, and angle, enabling the production of consistent and high-quality bends. Advanced features such as CNC (Computer Numerical Control) systems further enhance the precision and repeatability of the bending process, making these machines essential for both small-scale workshops and large manufacturing facilities.

Enhancing efficiency and accuracy

One of the primary advantages of utilizing advanced bending machines is the significant improvement in both efficiency and accuracy. Traditional manual bending methods are not only time-consuming but also prone to human error, which can lead to inconsistencies and defects in the final product. Automated bending machines, on the other hand, streamline the process by performing repetitive tasks with unwavering precision.

At Cojafex.com, our state-of-the-art bending machines are equipped with the latest technology to ensure that every bend meets the highest standards of quality. The ability to program specific parameters means that complex bends can be executed with minimal setup time, reducing lead times and increasing overall productivity. This level of efficiency is particularly beneficial for industries that require large volumes of accurately bent components, such as automotive, aerospace, and construction.

Versatility across industries

Bending machines are versatile tools that find applications across a multitude of industries. In the automotive sector, they are used to fabricate components like chassis parts, exhaust systems, and body panels, where precision and durability are paramount. The aerospace industry relies on bending machines to produce critical structural elements that must withstand extreme conditions while maintaining lightweight properties.

Construction and architectural firms utilize bending machines to create custom metal frameworks, railings, and decorative elements, enhancing both functionality and aesthetic appeal. Additionally, the medical device industry benefits from precise metal bending in the production of equipment and prosthetics, where exact specifications are essential for safety and performance. The adaptability of bending machines makes them a valuable asset in any field that demands high-quality metal shaping.

Why choose Cojafex.com for your bending needs

At Cojafex.com, we are committed to providing our clients with top-tier bending solutions tailored to their unique requirements. Our extensive range of bending machines includes both manual and automated systems, each designed to deliver exceptional performance and reliability. We understand that every project is different, which is why we offer customizable options to ensure that our machines meet the specific demands of your application.

Our team of experienced professionals works closely with clients to understand their needs and recommend the most suitable bending solutions. From initial consultation to final delivery, Cojafex.com ensures a seamless experience, backed by our dedication to quality and customer satisfaction. We invest in the latest technology and continuously update our equipment to stay ahead in the industry, providing our clients with the best tools to achieve their manufacturing goals.